Microbiology at the dairy plant is constantly interesting and important for the dairies. This seminar will explore the perspectives for positive microbiology, and how new knowledge about the effect of microorganisms in our microbiota can be applied positively into dairy products.

Also, the unwanted microbiology in the dairies which deteriorate the milk, and the dairy products will be explored. How to fight bacteriophages, yeast, moulds and thermoresistant bacteria throughout the steps of dairy processing – raw milk, processing, and shelf life.

Furthermore, the seminar will focus on the ones that are really unwanted at the dairy plant, such as Salmonella, Listeria, Mycotoxins and campylobacter – how to avoid these? The seminar will also seek answers to how approvals of fast detection methods is organized.

See programme HERE.

Presentations.

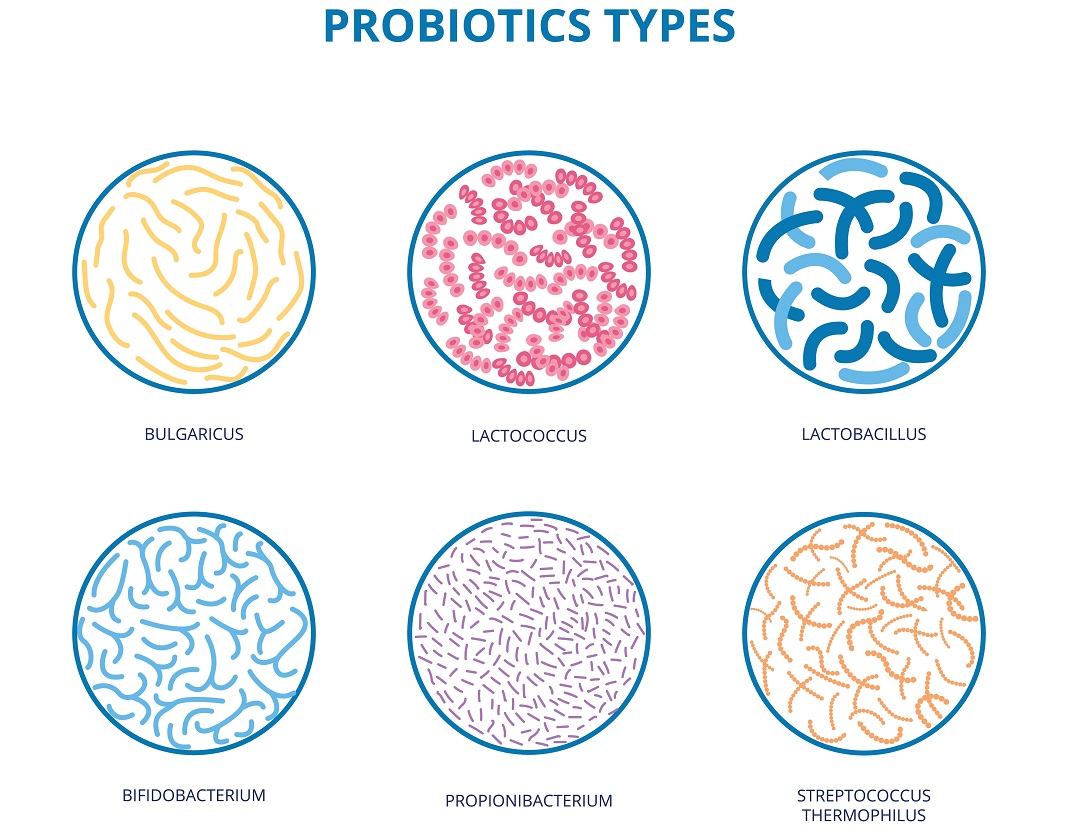

Probiotics – when can this term be used in the marketing of foods?

This presentation will explain use of the term probiotics in Denmark and answer questions such as “How can the term probiotics be used on food supplements?”

Furthermore, it will cover rules regarding the use of the term probiotics on other foods than food supplements e.g. how can yoghurt be labelled and finally what is the future process to allow the use of the term probiotics on other foods than food supplements?

The various nuances of kefir yesterday and today

One of the oldest fermented products derived from milk is certainly kefir.

Around the world, it represents for some markets a traditional product, still made with the materials and methods that tradition has allowed to be transferred.

For others, it is still an innovation and a discovery.

The kefir product and its variants, has particular characteristics of pleasantness and nutrition, making it more and more a market reality, not just a trend.

This presentation will also touch on the technological aspects of production.

The context related to the characteristics of current kefir cultures will also be evaluated, as well as the solution of common production problems.

Listeria monocytogenes in the dairy environment

Listeria monocytogenes is a foodborne pathogen which is commonly found in milk and as a contaminant in dairy processing plants. Proper pasteurisation is effective in destroying Listeria monocytogenes, but post-contamination can occur and thus possess a risk for human health. In addition, Listeria monocytogenes can form biofilms, grow at low temperatures, survive freezing, and can be found in all stages of food processing. Food producers are responsible for ensuring the safety of their food products and complying with the microbiological criteria for foodstuffs in the European Union. Amongst dairy products, cheese represent excellent conditions for survival and growth of Listeria monocytogenes. The risk of Listeria contamination of cheeses may be reduced by application of protective cultures, which can serve as an additional hurdle in a food safety concept.

Microorganisms in plant-based dairy substitutes – new challenges, new opportunities

Plant-based dairy substitutes should look and taste like dairy products. But in many cases, the composition of their microflora differs clearly from the microbial landscape in dairy products. Consequently, the microbial risks as well as the causes of microbial spoilage are different in these substitute products. This requires that the assessment of food safety and shelf-life must be approached in a different way, and if necessary, specific solutions to protect these substitute products have to be developed.

One of the most promising strategies to ensure food safety and shelf-life is the use of food-grade microorganisms that are especially adapted to dairy substitute products. Such bacteria cultures have the potential as biopreservatives and furthermore can also be of use to improve taste and texture of such substitutes or even increase their nutritional value.

UV technology and its effect on unwanted microorganisms

Thermal treatment is used in the dairy industry to ensure food safety and prolong shelf life. Cold pasteurization is a non-thermal treatment, which instead of heat uses UV-light to inactivate unwanted microorganisms. The technique is a more sustainable approach to microbial decontamination with highly reduced energy and water consumption. Cold pasteurization is applicable to non-see-through liquids such as milk, because of an optimum flow pattern of the product and light filters ensuring high product quality.

The technology and the mechanism behind the germicidal effect by short wave UV-light will be explained. Additionally, different applications to dairy products and results of microbiological inactivation will be discussed.

Whey quality in relation to powder production

Arla Foods Ingredients (AFI) produces wheybased ingredients for infant formula, medical ap-plications and sports nutrition. Whey from cheese production is used to produce high quality end-products to our customers. In this process we filtrate and concentrate components in the whey many times, and unfortunately also passively concentrate the unwanted microbial content of the whey. The microbial quality of our raw material, the cheese whey, is thus of paramount importance to secure quality and food safety of our products. This highlights the need for a strict quality control from our whey suppliers, the dairy plants, which includes all steps in the cheese and whey production from raw materials to ingredients and production process. This presentation will give examples on the importance of the microbial quality in the entire value chain from dairy farm to dairy plant and to our end-product protein and lactose powders in or-der to ensure high quality products void of unwanted microbiology.

Fast detection of bacteriophages at dairies

Bacteriophages are viruses that infect bacteria, as such they are present in environments where bacteria exist. Therefore, dairy plants represent a perfect habitat for lytic phages leading to severe problems during fermentative processes, such as slow acidification and consequent loss of batches. Liquid splashes and air displacement around factory equipment generate aerosols, which are recognized as a major route of phage contamination in dairies. Thus, phage detection and monitoring are key in order to reduce the risk of starter culture infection and minimize economical losses. Classical detection methods are time consuming and results are often non reproducible among laboratories. Hence, a fast qPCR method has been developed to detect and quantify the two main groups of bacteriophages infecting Lactococcus strains. This qPCR method proved to be a beneficial and easy tool to be incorporated into dairy sites routines, indicating phage pressure to enable fast decision making for corrective measures at factories.

Bacteriophages: from enemies to allies of dairy plants

Bacteriophages (phages), viruses naturally killing bacteria, are promising alternatives to antimicrobials, as demonstrated by the successful use of phages to control pathogens in humans, plant, animals and food.

In the dairy sector, phages are historically known as an enemy because they put at risk starter cultures.

Nevertheless, the growing knowledge about phages infection mechanisms and their specificity lead me to reconsider phages as a resource to face the novel challenges that this sector is facing, such as ensuring food safety and increasing the sustainability of the process. Here I propose the implementation of phage solutions to:

- improve the safety of powder infant formula by using phages against Cronobacter sakazakii;

- increase the efficiency of dairy filtration systems by using phages for biofilm removal.